|

| Contact:Mi. Luo

Tel:86-0755-28111531 27524572

Fax:86-0755-29010781

Mail:szshitongrg@163.com

URL:www.openecm.com

Add:Workshop, zone a, floor 4, No. 69, Langkou Industrial Park, Langkou community, Dalang street, Longhua District, Shenzhen |

|

|

|

|

|

|

|

|

|

| |

|

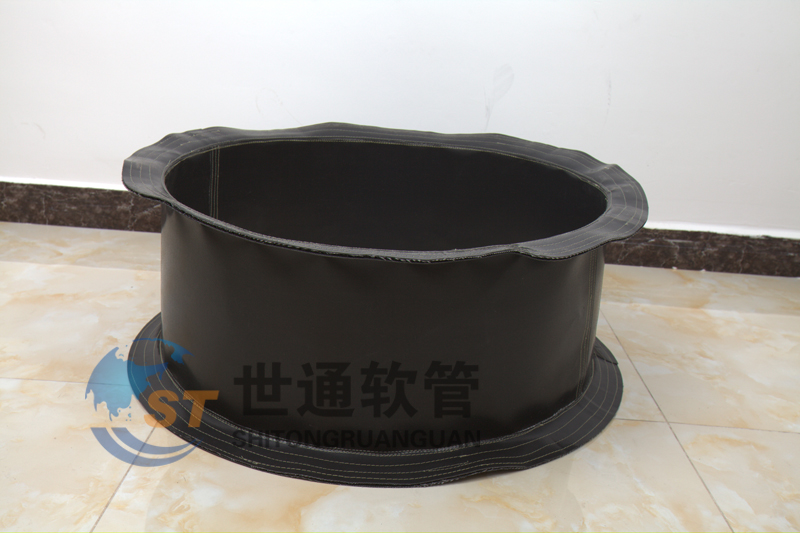

| Product Name:ST001015 circular soft connection |

| Product Name:ST001015 |

|

| Product Description |

|

Performance characteristics:

This product has unique high temperature resistance, air permeability, aging resistance, strong softness, good toughness and strong air tightness. It is a multi-purpose, high-performance synthetic material, widely used in aerospace, chemical large-scale power generation equipment, machinery, metallurgy, fire protection, grain depot fan ventilation and other fields.

It has the functions of fire prevention, smoke exhaust, noise and vibration isolation, and can be applied to the flexible connection and variable diameter interface of building smoke exhaust system. It is an ideal building smoke exhaust material. Its characteristics of high temperature, high pressure, gas flow rate of up to 20 meters per second, long life, acid, alkali, oil, corrosion resistance, moisture resistance, light volume, easy installation.

Attributes: silence, vibration isolation, absorption of fan noise, isolation of fan, vibration between ducts, constant temperature, humidity, corrosion, acid.

Temperature range: under 300 degrees, the temperature can be used for more than 6 hours, 250 degrees can be used for a long time, resistance to instantaneous high temperature 600 degrees, and still maintain good material performance at low temperature of -70.

Material: Double-layer silica-titanium gel, stainless steel wire, glass fiber blended, high-performance synthetic material.

The circular soft connection, the soft connection of the fan, the high temperature resistant and soft bonding material in the thermoplastic plastic forming process, because of the change in the volume of the crystalline form, the strong internal stress, the large residual stress in the plastic parts, the strong molecular orientation, and so on, the ratio of shortening to the thermosetting plastic is larger and the shortened rate is wide, Other shortening after forming, annealing, or humidifying treatments are also generally larger than those of thermosetting plastics.

The melting material and the cavity surface touch the outer layer and immediately cool down to form a low density solid shell. Because of the poor thermal conductivity of plastics, the inner layer of the plastics is slowly cooled to form a shortened high density solid layer. So the wall thickness, slow cooling, high density layer thickness is shortened. In addition, there are no embedded parts and inserts planning, and the number directly affects the direction of the flow of material, the dispersion of density and the reduction of the resistance, so the characteristics of the plastic parts have a great influence on the shortening of the size and the direction.

Order requirements: made according to the size of the drawings.

|

| Print - Close - Back |

|

|

|